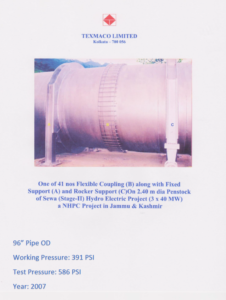

Baker Series 200 Couplings

Application:

Baker Flex Couplings are used to provide a flexible connection between two plain end pipes with the same pipe OD.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

Application:

Baker Series 208 are used to provide a flexible connection between two plain end pipes with large pipe gap.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Lengths: 16”, 24”, special lengths also available

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

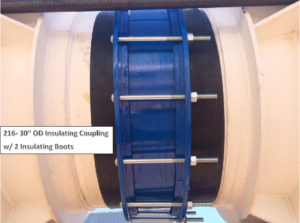

Application:

Baker Series 216 Insulating Couplings are used to provide a flexible connection between two plain end pipe, while providing electrolytic isolation.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Insulating boots will be provided to isolate pipe ends

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

Insulating Boot

NBR (Buna-N) per ASTM D2000

SBR (Buna-S) per ASTM D2000

Application:

Baker Series 212 Transition Couplings are used to provide a flexible connection between two plain end pipes with the same nominal pipe size.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

Application:

Baker Series 220 Reducing Couplings are used to provide a flexible connection between two plain end pipes with different nominal pipe sizes.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

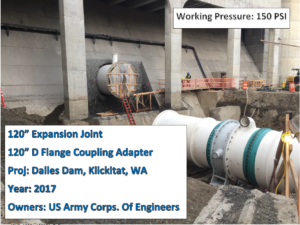

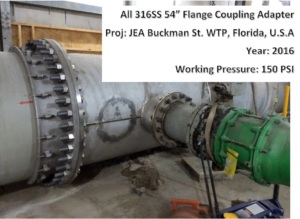

Baker Series 600 Flanged Coupling Adapters

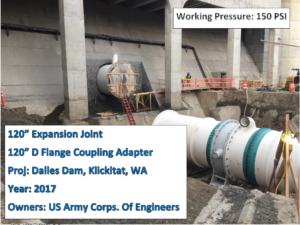

Application:

Baker Flange Coupling Adapters (FCA) are used to provide a flexible connection between plain end pipe and flanged end connection.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

Application:

Baker Flange Coupling Adapters (FCA) are used to provide a flexible connection between plain end pipe and flanged end connection with different pipe sizes.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C219 (Couplings standard for plain end pipe).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- All dimensions are in inches. Flexible couplings do not provide against pull out of pipe. Pipe stops, and anchor pins can be provided if required. Suitable anchorage may be required to prevent pull out of pipe.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

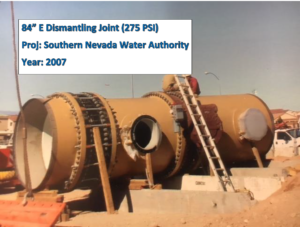

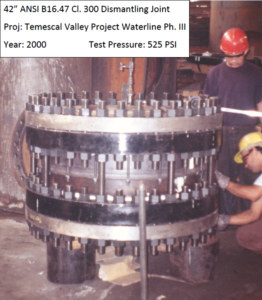

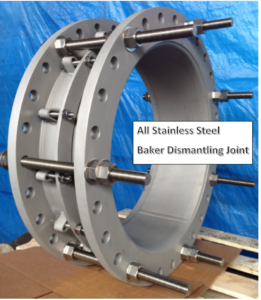

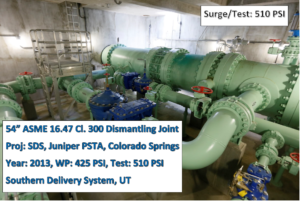

Baker Dismantling Joints (BDJ)

The Baker Dismantling Joint is a double-flanged pipe fitting. Dismantling Joints allow for easy installation and continued maintenance of the fitting. Typical applications include pumping stations, water treatment works, sewage treatment works, plant rooms, meter chambers, power generation equipment and gas distribution stations. Baker Dismantling Joints can accommodate custom longitudinal adjustment dependent on the diameter. Once adjusted the Dismantling joints movement can be restricted by using the supplied tie rods. The Dismantling Joints are designed such that the restraint system does not extend outside of the flange diameter. Baker Dismantling Joints can be easily installed with minimal special equipment needed. Dismantling Joints can be made with any nominal size, with common flange drillings to mate with AWWA C207 Class D, E, and F flanges with a working pressure of 150 PSI and higher. Specials can be made based on specific project requirements. Dismantling Joints are shipped with SBR gaskets but can be changed based on different applications.

Application:

Baker Dismantling Joint is a double-flanged pipe fitting. Dismantling Joints allow for easy installation and continued maintenance of the fitting.

** Available in All Stainless-Steel Construction **

Material Specifications:

- Dismantling Joints shall meet or exceed provisions of ANSI/AWWA C219.

- Alternate materials and coatings can be provided as required by project specifications.

- Designed so that no part of the restraint system extends beyond the flange diameter.

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

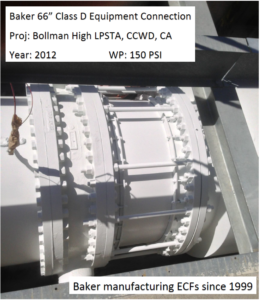

Baker Equipment Connection Fittings (BECF) or Double Dismantling Joint

Baker Equipment Connection Fittings combine two flange couplings with a spool piece to provide restraint for misaligned flanged fittings. Baker ECFs are capable of accommodating a minimum of ¼” offset and 1-2° deflection. Like Baker Dismantling Joints, Equipment Connections have an adjustable laying length to allow for the ease of installation of external components. Tie rods provide a means of restraining the joint and are easily installed or removed. Baker ECFs are compatible with various flange types, including AWWA C207 Cl. D, Cl. E, and Cl. F flanges. The laying length of the equipment connection can be made to accommodate the span between pipe fittings. ECF come with standard hardware, but also available with stainless steel.

Application:

Baker Equipment Connection Fittings combine two flange couplings with a spool piece to provide restraint for misaligned flanged fittings.

** Available in All Stainless-Steel Construction **

Material Specifications:

- ECFs shall meet or exceed provisions of ANSI/AWWA C219.

- Alternate materials and coatings can be provided as required by project specifications.

- Designed so that no part of the restraint system extends beyond the flange diameter

Middle Ring

ASTM A36/ A53

Follower Ring

ASTM A576/ ASTM A36

Gasket

STANDARD: Molded or extruded styrene butadiene rubber (SBR) per ASTM D2000 | Maximum recommended operating temperature = 150°F

OPTIONAL: Molded or extruded NBR (Buna-N) per ASTM D2000 | Maximum recommended operating temperature = 220°F

OPTIONAL: Molded or extruded EPDM per ASTM D2000 | Maximum recommended operating temperature = 300°F

OPTIONAL: Extruded Viton and Neoprene Gaskets

Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

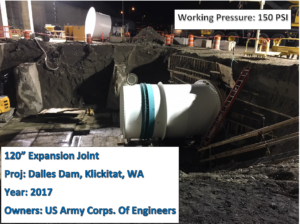

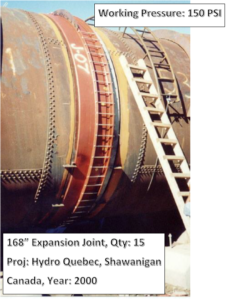

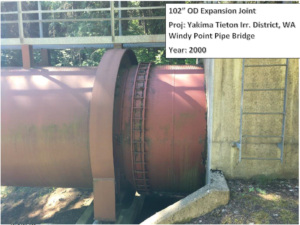

Baker Series 401/403 Expansion Joints

Application:

Baker Series 401 Expansion Joints are used to provide connection between plain end pipe where there is a large, concentrated movement. Movement is not restrained by the expansion joint.

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C221 (Standard for Fabricated Steel Slip-Type Expansion Joints).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Slip Pipe

Hard Chrome plated on machined surface or stainless-steel to meet AWWA C221.

Packing

Alternating combination of rubber and impregnated flax for water service.

End Preparation

Flanged, Beveled, or Plain for Butt Strap, and other special preparation per specification

Optional Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)

Application:

Baker Series 403 Expansion Joints are used to provide connection between plain end pipe where there is a large, concentrated movement. Movement is limited to ± 5".

Material Specifications:

- Couplings meet or exceed provisions of ANSI/AWWA C221 (Standard for Fabricated Steel Slip-Type Expansion Joints).

- Alternate materials and coatings can be provided as required by project specifications. Contact Baker.

- Sizing information is for commonly used pipe sizes and pressures. Contact Baker for design of sizes not shown.

- Pipe Material: Steel, cast iron, asbestos cement, plastic and other types of pipe

** Available in All Stainless-Steel Construction **

Slip Pipe

Hard Chrome plated on machined surface or stainless-steel to meet AWWA C221.

Packing

Alternating combination of rubber and impregnated flax for water service.

End Preparation

Flanged, Beveled, or Plain for Butt Strap, and other special preparation per specification

Optional Flange

AWWA C207/C228 D, E or F

ANSI Class 150, 250, 300

ANSI/ASME B16.47

Metric PN10, PN 16, PN25, PN40, and others

Weld Neck Flange, Flat or Raised Face Flange, or Special Ring Joint Facing (Groove) Flange

Lining

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Coating

Baker Shop Coat for corrosion protection in transit-no sandblast

NSF 61 Coatings Available

NSF 61 Fusion Bonded Epoxy per AWWA C213

NSF 61 Liquid Epoxy per AWWA C210

Hardware

STANDARD: Corrosion resistant high strength low alloy steel (fasteners) per AWWA C111 and ASTM A242

OPTIONAL: Type 304 stainless steel per ASTM A193 and A194

OPTIONAL: Type 316 stainless steel per ASTM A193 and A194

OPTIONAL: Zinc plated with di-chromate seal (electro-galvanized)